Customer Service

Program

Management

New Parts

Kick Off & Tracking

Real Time

Capacity Planning

Status

Updates

At High Tech Solutions, we think like the Customer with responsive, dedicated Program Managers here to assist you and provide inventory management, min/max and consumption based orders, value engineering and discounts. We work to build and maintain long term relationships with our customers to understand your needs. Will design processes to meet your requirements and ensure you have quality parts delivered when you want them.

CNC Machining

Production Capability

Our operations provide the best cost, quality and value by applying World Class Lean Manufacturing principles and systematic elimination of Waste. Complexity turns into commodity with standardization of manufacturing processes. Through common sense and teamwork we continuously improve our operations to eliminate waste, while manufacturing products that meet customer demand.

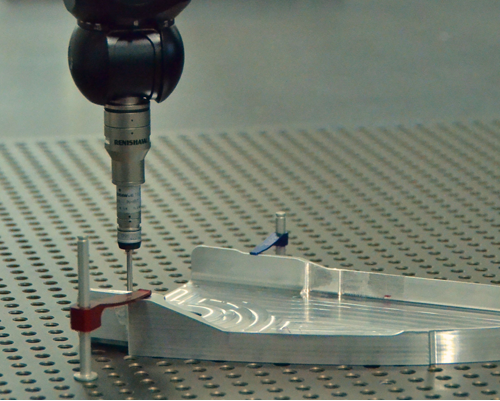

Quality Capability

We implement processes that ensures a product is brought about by consistent commitment to Quality and standards that achieve product conformity free from defects, deficiencies and significant variations. These processes focuses on preventing quality issues before they happen as well as identifying quality issues in manufactured products.

Premium equipment needs to be driven by premium software and technology! High Tech has invested in industry leading software and developed world class processes which allow us to meet our customers expectations accurately and efficiently. We execute and maintain an OEM approved DPD/MBD process to manage customer requirements from “Art to Part”.

Engineering & Programming

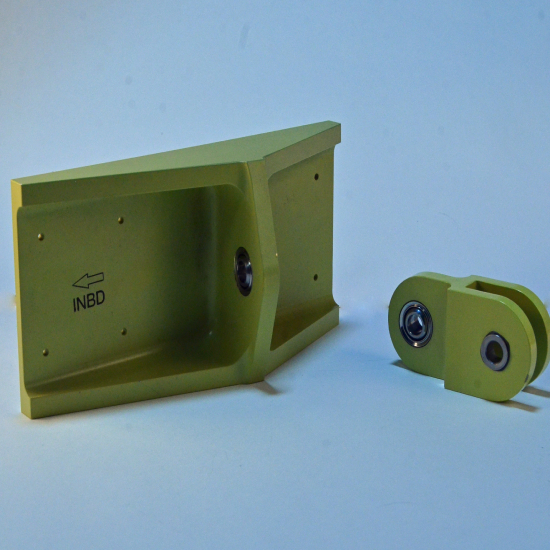

4 & 5 Axis Capability

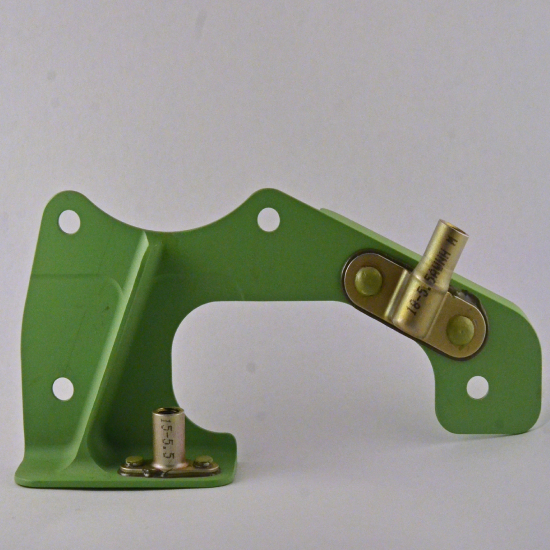

CNC machine capabilities include 3, 4, and 5 axis vertical and horizontal machining centers and multi-axis lathes equipped with live tooling and sub-spindles which allow us to complete parts in one operation.

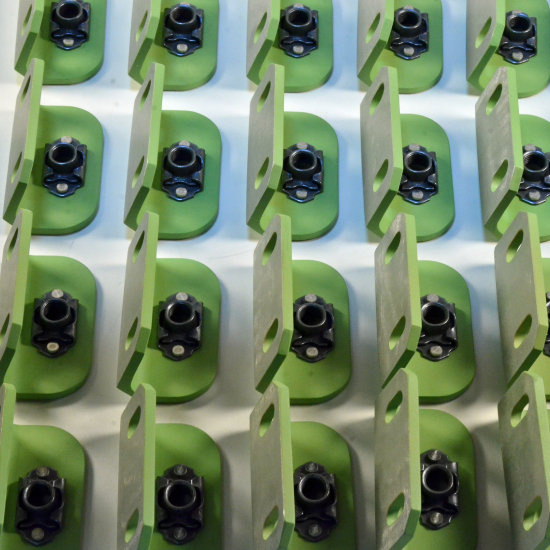

Assembly

Benchtop Assemblies

Our focus is to strengthen our customer relationships by supplying bench top assemblies which increases our organic growth and provides added-value required in the ever-demanding Supply Chain. Our trained and skilled assembly personnel install a variety of aluminum and steel rivets, Hi Lok’s, and fasteners into sub-assemblies. They also work with various sealants and adhesives. Some of our bench top assembly processes include:

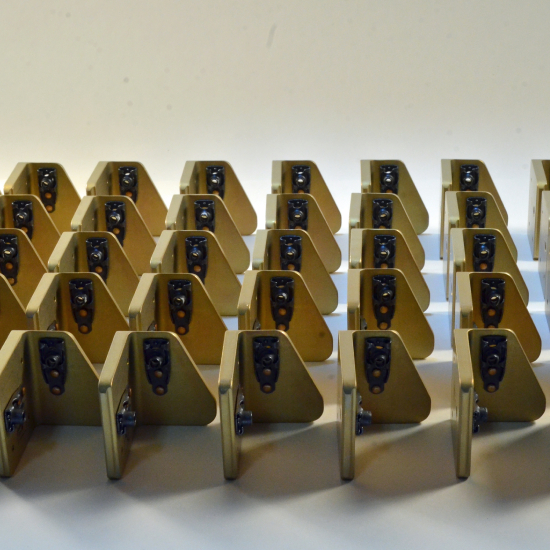

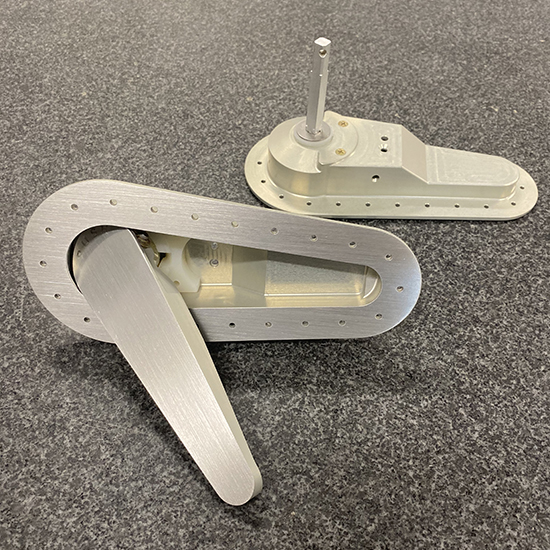

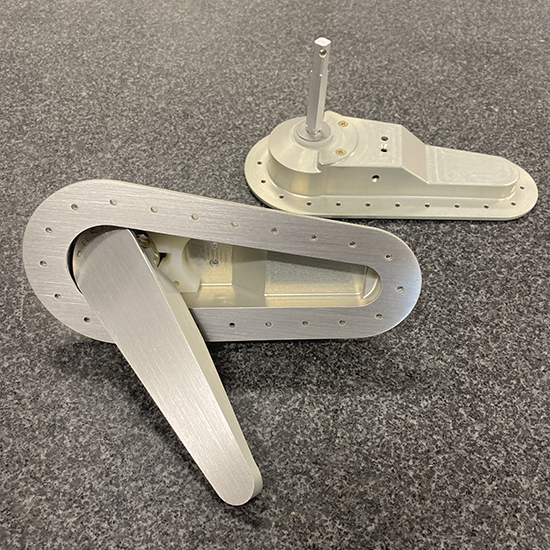

Handle and Latches

Mechanical Assemblies

We supply direct to the OEMs, various handle, latch and mechanical assemblies for several aircraft in the Business Jet and General Aviation markets. Quality, reliability and cosmetics are all critical because these products will interface directly with the plane’s operators and owners.